Having messed around with this for a while, it's time to come up with the list...Autodesk is making progress with the app, but there are still things that really need to be addressed. Most of this stuff can be worked around, but if I was the product manager, this is what I would focus on...

1. Conduit, Cable Tray, Bus Duct, Flat Oval Duct...'nuff said.

2. Connectivity into linked files - ultimately, there's going to come a day when a project simply has to be broken up. The ability to read a connector's info through a linked file (without have to place a dumb connector in the current project) is vital. We've got that for the most part in ACAD MEP - at least in there we can pick up on pipe, duct, cable tray and conduit connectors...

3. Which leads to point 3 - ACAD MEP SNAPS!!! create connection point snaps -add this functionality to Revit- it works great in ACAD MEP and really helps clarify what the connection point is..

4. Make the undefined connector type (the general system) usable as a source equipment connection. I had a bizarre conversation with someone that tried to tell me that pumps are only considered inline accessories. Tell that to the base mounted pump. It can't be placed like an inline pump the way the connectors are defined - so autolayout freaks out when you try to treat it as any other device in a system. And in many cases, the pump is the primary source of fluid flow (see sprinkler system) - the valve is already treated as an inline component and behaves correctly. Our workaround has been to make a copy of the pump family, and then set the connector to a specific system, such as fire protection wet, hydronic supply, etc...

5. Which leads to point 5 - open up the systems to allow user-added options. There are so many subsystems under hydronic piping, "other", supply, return, exhaust...there has to be a better way to do it. If you can't open it up, then allow for a subsystem option that lets the user control the sizing and design parameters - not every supply duct will be sized the same way, and a subsystem would make it easier to control this.

6. Schematic Symbol improvements - try making a custom valve in Revit MEP, or editing an existing one...lots of fun here with no documentation. We're working on it, but getting some input somewhere from Autodesk would be really helpful. And having a riser/schematic diagram tool would be nice, but for now we're using the tools in ACAD MEP and importing the DWG into the project.

7. Excel links - bidirectional and in the program, not having to go through a DXF or DWG...'nuff said. Not every engineer is gung ho about using SQL, VBA, OBDC (or is that ODBC)....know thine audience...and keep it simple.

8. Panel schedule editing tools....that work easily...graphical interface perhaps? My ears get burned on this one by the EE's every day for both MEP applications - nobody does them the same way, every state has its own requirements for how these should look and feel, and what information goes in them - so we've got to be able to easily edit them. (side note for schedules - allow for a predetermined width and height in the formatting, instead of asking the user to drag the columns on every project).

9. I compliment the pace in which Autodesk is getting content together for the product - much faster than ACAD MEP...now make sure you have the parts such as toilet carriers, etc. that the plumbing designer never used to show - but beats us up about every day. If they're going to have to model it, then by God, let's model it right...

10. Copy/Monitor - wow, this one's getting hammered, but it's got to work right or be replaced. Either make constraints work through a linked file (such as using a placement constraint to get a light to stay aligned horizontally with a ceiling grid) or get the rest of the components to be copy monitored through a linked file (without flipping it around, changing alignments, breaking cleanups) - including ceiling grids.

11. Get the piping guys from ACAD MEP to come on over and help...it's vastly better in 2010 but still needs some work - these guys have got it nailed in ACAD MEP 2010 - build off of what they know needs to happen...and make it happen. It needs the right connectors (separate from the pipe and fittings), insulation, etc. but it doesn't need to be at the gasket/bolt/weld level - you're getting warmer... Single line and double line concurrently in plan display at the same time is a must.

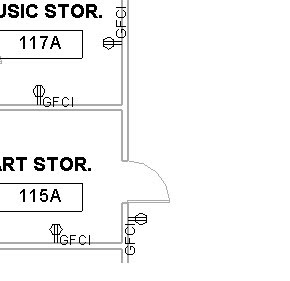

I'm not all complaint - analysis and HVAC in the program are working great and just need a few tweaks here and there (did I mention oval duct?). Scheduling and coordination have always been hallmarks, I'd add soft interference and clearance detection if at all possible. Lighting fixtures rock in this release, and the realtime data analysis is always sweet...and now that I'm used to it, the ribbon is very cool, the interface looks much more professional than previous releases. Electrical is definitely getting better, but I'd love to see a right-reading setting for embedded annotations (as well as a separate grip for location options - again, AKA ACAD MEP devices).

If you have some things you'd like to see, comment on the post - I'd love to hear from others as well...

The workarounds? for now you'll need to attend this year's class at AU I'm doing to get them all in one document (Revit MEP: Powerful Tips and Tricks...this is my shameless plug) - see you there!

David B.